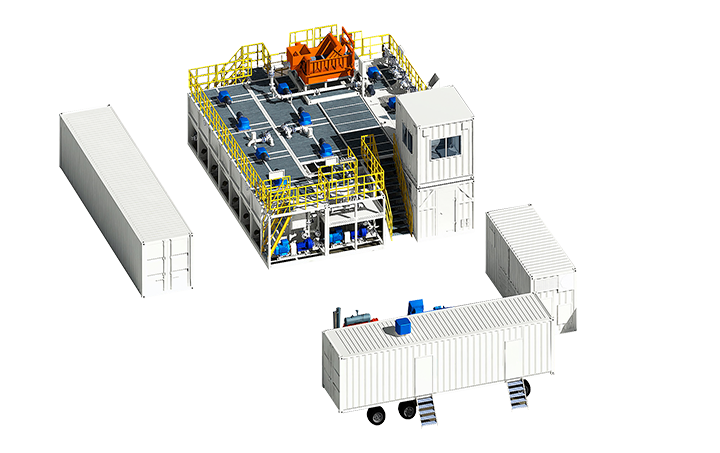

Waste re-injection is a drilling cuttings technology independently developed by Jereh. After more than ten years practice verification, it has been applied maturely. Suitable for drilling cuttings, waste mud, frac flowback and municipal sewage. By grinding and slurrying, the solid particles are treated to a predetermined particle size, so that the waste becomes a homogeneous slurry having a certain carrying capacity, then the re-injection requirement is achieved. It is permanently sealed to selected formation areas by high-pressure injection, with the technical advantages of wide application range, low processing cost, large processing capacity, realizing“zero” emission and permanent storage of pollutants.

This equipment can treat a variety of wastes, such as drilling cuttings, oil sands,

waste drilling mud, oily wastewater and fracturing flow-back;

During the process, there is no heating, no exhaust gas emission, no secondary pollution, the treated pollutants are permanently sealed underground, which does not occupy the surface area and is more environmentally safe;

It can be processed while drilling or centralized, and can be treated on offshore

& onshore platform, the process is mature and stable, while the processing cost is

very low;

The monitoring system realizes visual management and centralized remote control, and the operation is simple, intuitive and convenient; the on-site operation area is concentrated so that the number of operators can be reduced.

Equipment Model | Design Capacity |

THZ01B | 3m3179;/h |

THZ02B | 6m3179;/h |

THZ03B | 9m3179;/h |

THZ04B | 12m3179;/h |