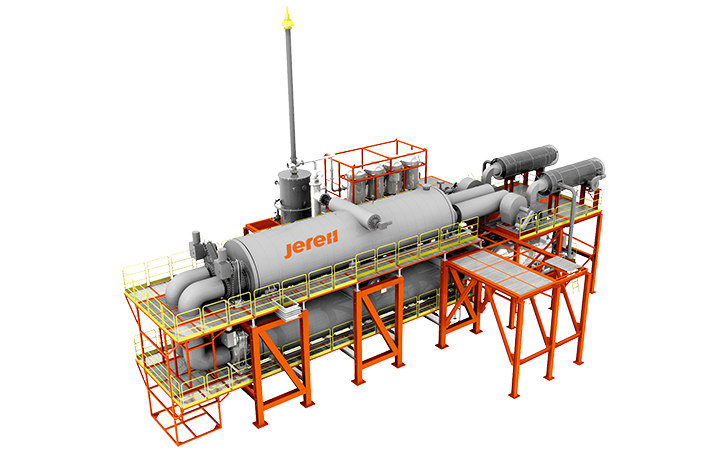

By means of radiation heat transfer in the central pipe of high temperature flue gas, the oily waste could be separated by controlling the heating temperature and heating time under the anaerobic condition. It can be widely used in the treatment of oily waste such as waste mud, oily drill cuttings, tank bottom sludge, oil pit sludge. The structural design of double helix differential meshing can completely solve the coking problem in the oily waste heating process.

Equipped with safety valve overpressure protection and fire arrester tempering

protection, alarm-interlock-emergency stop linkage control could ensure the safeoperation of the system.

Central tube radiation heat transfer technology, through the use of temperature

gradient control, flue gas waste heat reuse and other measures, the thermal efficiency is above 25% higher than conventional equipment.

The central radiant tube adopts professional heat-resistant steel, the steel type

is matched with temperature grade, and the radiant tube is rotated to make it heat evenly, so that the furnace tube lifetime could be increased.

With data acquisition system and central control system, we could realize fully

automatic closed-loop system control, realize Web publishing through Industrial

Ethernet, and support remote monitoring and maintenance.

| Equipment Model | Design Capacity |

| TRF120X2B | 30000-60000t/a |

| TRF240X2B | 60000-120000t/a |

| TRF70X1B | 15000-30000t/a |

| TRF140X1B | 30000-60000t/a |