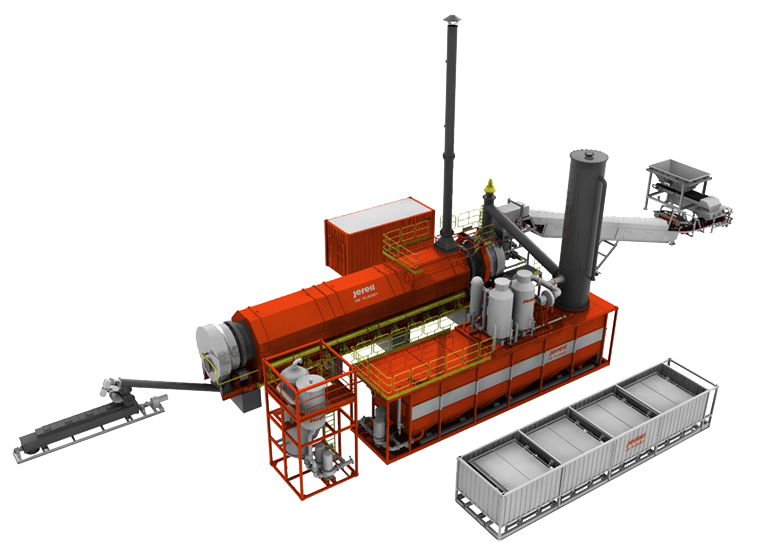

It is mainly used in VOCs, SVOCs soil remediation after the relocation of chemical plants or pesticide plants, and also oily waste treatment in oil and gas fields. Under anaerobic conditions, through indirect heating on the input material, we can achieve contaminated soil remediation and harmless treatment of oily waste. This is a new generation of thermal desorption products developed by Jereh based on years of application experience and combined with the characteristics of thermal desorption equipment at home and abroad.

Modular design, small area occupy, fast assembly and convenient transportation, are suitable for periodic operation in soil remediation;

The material mixing system could realize evenly heating and improve efficiency; real-time temperature monitoring ensures heat exchange efficiency, flue gas waste heat is fully recycled to ensure energy saving and low operating cost;

The kiln body inclination angle and the cylinder rotation speed can be flexibly adjusted according to the material, and can effectively treat a variety of organic pollutants;

With Four-level safety control system and redundantly designed key components, we could ensure long service lifetime and system safe operation. The overall PLC automatic control system enables dynamic monitoring and storage in the production process, making the data traceable and easy to operate.

Equipment Model | Design Capacity |

TRF30LB | 10000-20000t/a |

TRF70LB | 30000-70000t/a |

TRF140LB | 60000-140000t/a |