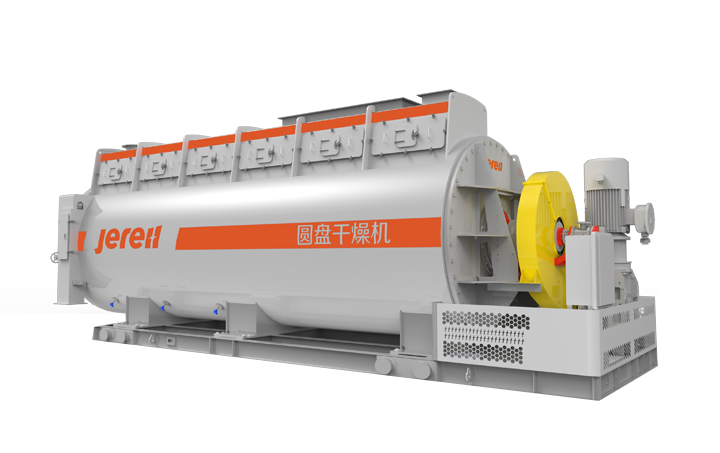

Disc drying equipment can be used in various municipal sludge and industrial sludge drying reduction. It consists of a double shell and a rotor with a hollow disc on which an adjustable pusher is mounted. At work, it can heat the material and push it forward. Sludge with 80% moisture content can be reduced to about 40% after drying and dewatering by disc dryer, and then transported or finally disposed.

The machine layout is simple, modular layout, small footprint, fast assembly, convenient transportation, high degree of automation.

Internet of Things cloud platform remote monitoring, timely warning equipment abnormal situation, more in-depth and comprehensive processing, to ensure long-term stable operation of user equipment.

Part of the heat is recovered, drying efficiency is also improved.

Improve the heat exchange surface properties, prevent sticky material, improve the surface heat exchange efficiency at the same time, but also to deal with viscous industrial sludge.

Precise calculation and finite element analysis, reasonable structural design: eliminate the stress concentration of bearing parts, so that the stress distribution is uniform.

| Model | Production Capacity | Evaporation | Heat Exchange | Rated Steam Pressure | Rated Steam Temperature | Rotating Speed | Motor Power |

| GYPD170 | 50 | 1300 | 190 | 0.6 | 160 | 1-3 | 35 |

| GYPD370 | 100 | 3000 | 400 | 0.6 | 160 | 1-3 | 55 |